-

How is co-extruded self-adhesive protective film different from traditional protective film?

1. Production process:Co-extrusion self-adhesive protective film: This protective film is produced by co-extrusion technology. Co-extrusion technology extrudes ...

Industry News -

How does the thickness of co-extruded self-adhesive protective film affect its performance?

1. Protective performanceThe thickness of the co-extruded self-adhesive protective film directly determines the strength of its protective performance. Thicker ...

Industry News -

How does machine stretch film provide excellent puncture and tear resistance?

Machine stretch film provides excellent puncture and tear resistance through a combination of its material composition, manufacturing process, and design. Typic...

Industry News -

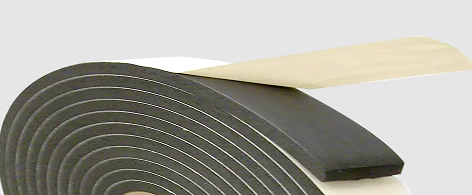

What are the application scenarios of double-sided foam tape?

1. Construction and decorationIn the field of construction and decoration, double-sided foam tape is widely used due to its excellent adhesive properties and cu...

Industry News -

How Does Machine Stretch Film Improve Load Stability During Transport?

1.Uniform Tension and Tight WrappingMachine stretch film offers a significant advantage in load stability due to the consistent and uniform tension applied duri...

Industry News -

What Are the Most Effective Uses for Sticky Mats in Various Environments?

1. Cleanrooms and Controlled EnvironmentsSticky mats are widely used in cleanrooms and other controlled environments to maintain stringent cleanliness standards...

Industry News -

How to properly install and remove Co-extruded Self-Adhesive Protective Film?

1. Detailed installation steps:Prepare the surface: Before installing the Co-extruded Self-Adhesive Protective Film, make sure the surface is clean, dry, and fr...

Industry News -

How does protective film prevent scratches and stains on window glass surfaces?

1. How protective films workThe basic principle of protective films is to form a protective layer on the surface of the window glass to prevent foreign objects ...

Industry News -

How does Self-adhesive Protective Film protect surfaces from damage?

1. Physical protection layer: Self-adhesive Protective Film is usually made of high-quality wear-resistant materials such as polyethylene (PE) or polypropylene ...

Industry News -

How to choose the appropriate material and thickness of self-adhesive protective film?

1. Surface type:Different types of surfaces have different requirements for Self-adhesive Protective Film. For example, metal surfaces may require protective fi...

Industry News -

How to prevent the Sticky Mat from moving or sliding during use?

The Sticky Mat may move and slide during use. This is often related to the underlying material of the Sticky Mat. High friction or non-slip materials such as ru...

Industry News -

What should be paid attention to during the transportation and storage of PE Stretch Film?

Due to the particularity of PE Stretch Film, we need to pay special attention to it during storage and transportation to ensure that its quality and performance...

Industry News

English

English

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى