Our protective films can protect numerous products to avoid scratch, mark, damage and dirt at the process of bending, pressing, roll forming, painting, transportation and installation etc.

China protective film manufacturers and protective foils suppliers

. Our protective films can protect numerous products to avoid scratches, mark, damage and dirt at the process of bending, pressing, roll forming, painting, transportation and installation, etc. The protective film can be easily applied and removed, leaving no residue glue after removal. Thus with the protection of the protective film, people can enhance the market competition of their valued products!We are a professional protective film manufacturer. Our goal is to provide the market and our customers with customized protective film and tape with following properties:

-

Right adhesion match

Right adhesion matchGetting the right match between protective foil and your products/ surfaces requires lots of expertise. At Qida Tape, our professional engineers and technicians have the expertise to help ensure no residue glue after removing the protective film.

-

Good UV resistance and weatherability

Good UV resistance and weatherabilityDepending on customers’ requirements, Qida supplies UV-treated protective film that can be exposed outdoors for 12 months. There is no effect on adhesion level in different environments and the adhesive does not react with other products’ surfaces.

-

Extensive selection with customized features

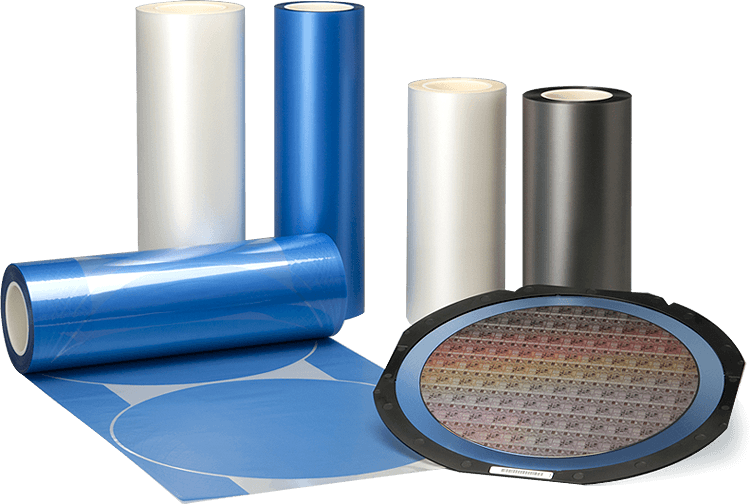

Extensive selection with customized featuresQida can supply protective tape with acrylic water, acrylic solvent and natural rubber adhesive. Protective tape can be printed with a customized logo, perforated, treated with suitable tensile strength and elongation as well as fire-retardant properties.

Our teams are committed to preserving everything that holds value by creating a responsible industrial community and doing their best in all our operations while at the same time seeking to protect the planet.

-

What Are the Advantages of Using Machine Stretch Film for High-Speed Packaging Lines?

Increased Efficiency and Speed Machine stretch film significantly increases the speed and efficiency of packaging lines. Unlike manual wrapping, which is slow and prone to human error, stretch film machines can wrap hundreds of units per ho...

Read More -

Why Is Breathable Surface Protection Felt Essential for Preventing Moisture Damage?

Understanding Breathable Surface Protection Felt Breathable surface protection felt is a specialized material designed to shield surfaces from physical damage, moisture, and environmental hazards while maintaining air circulation. Unlike tr...

Read More

English

English

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى