Cat:Glue -coated Protective Film

● Protects carpet against staining, paint spillage and dirt during painting, building, remodeling, plastering, tiling, decoration, general maintenance...

See Details

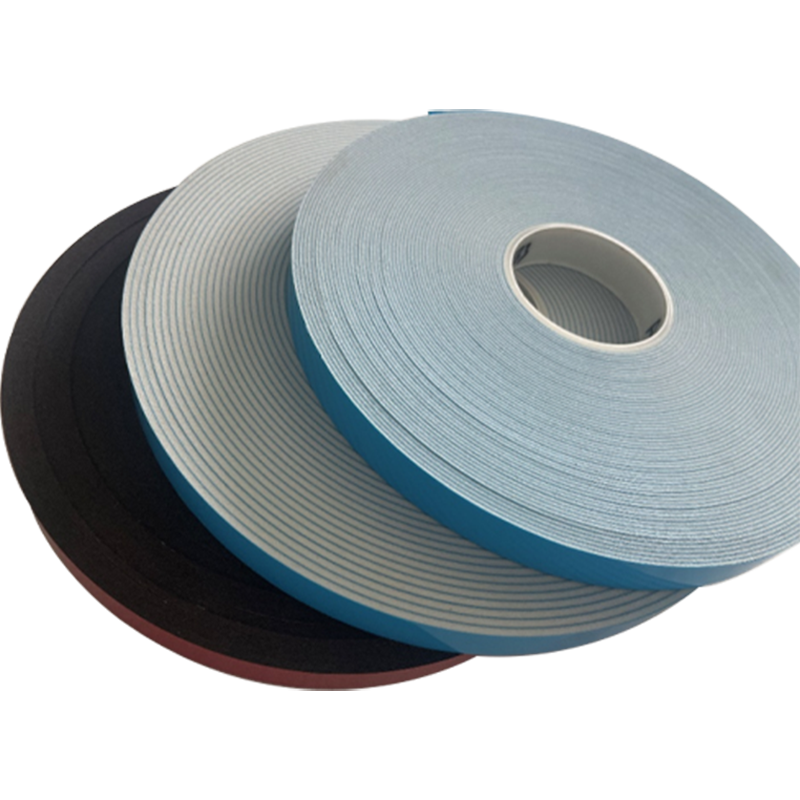

When choosing foam materials, double-sided foam and single-sided foam each have their unique advantages. The main difference between the two lies in their structure, applications, and cost-effectiveness.

As the name suggests, double-sided foam has adhesive on both sides of the foam. This allows it to bond two surfaces together. Double-sided foam is typically made of high-quality foam material with a strong adhesive coating, making it ideal for applications where both sides of an object need to be attached. Due to its structure, double-sided foam offers a strong bonding force and is suitable for joining various materials.

Single-sided foam, as the name implies, only has adhesive on one side, while the other side remains non-adhesive. This type of foam is typically used for adhering one object to a surface or providing surface protection. Single-sided foam is generally cheaper than double-sided foam and is commonly used for basic packaging needs due to its simpler structure.

Bonding Strength of Double-Sided Foam: Double-sided foam provides stronger bonding because both sides have adhesive. When securing objects, it evenly distributes pressure, preventing detachment due to uneven bonding. For instance, double-sided foam is ideal for securing curtains, flooring, or advertising panels, offering long-lasting and stable adhesion.

Bonding Strength of Single-Sided Foam: Single-sided foam, with adhesive only on one side, offers a weaker bond. It is typically used for attaching objects to a specific surface, such as in packaging or light-duty applications. While single-sided foam can meet basic needs, it may not provide sufficient support for high-demand applications.

Flexibility of Double-Sided Foam: Double-sided foam is suitable for more complex applications. Its dual adhesive sides allow it to bond different materials together. For example, in electronics, automotive parts, and advertising displays, double-sided foam can securely bond two surfaces, enhancing stability and reliability.

Flexibility of Single-Sided Foam: Compared to double-sided foam, single-sided foam has more limited uses. It is commonly used to adhere objects to one surface, such as in daily packaging, electronics protection films, and wall decorations. While its range of applications is more straightforward, it is adequate for many everyday needs.

Thickness and Density of Double-Sided Foam: Double-sided foam is generally thicker than single-sided foam, offering more cushioning. This makes it better for protecting fragile or high-value items during shipping. Additionally, double-sided foam typically has a higher density, which helps absorb external impact and protect items from damage.

Thickness and Density of Single-Sided Foam: Single-sided foam is usually thinner, making it suitable for lightweight item protection. While its cushioning properties are not as strong as double-sided foam, it can still meet the protection needs for lighter items. Single-sided foam is also typically more economical, making it ideal for large-scale use.

| Material Type | Features | Applications | Cost-Effectiveness |

|---|---|---|---|

| Double-Sided Foam | Adhesive on both sides, strong bonding | Industrial packaging, advertising, automotive parts | Higher cost, but durable and suitable for high-value items |

| Single-Sided Foam | Adhesive on one side, weaker bonding | Lightweight packaging, home decor | Lower cost, ideal for mass production, cost-effective |

Cost-Effectiveness of Double-Sided Foam: Due to its more complex production process and additional materials, double-sided foam generally comes at a higher price. However, it provides stronger adhesion and longer-lasting durability, making it ideal for high-demand projects. In industries such as industrial packaging and advertising, the benefits of double-sided foam justify its higher cost.

Cost-Effectiveness of Single-Sided Foam: Single-sided foam is more affordable, making it suitable for large-scale production and low-budget projects. It can fulfill basic adhesive needs at a lower cost. For applications where double-sided bonding is not required, single-sided foam is a more cost-effective choice.

Precision Packaging: Double-sided foam, with its stronger adhesive properties, is widely used for packaging delicate items such as mobile phones, electronic accessories, and instruments. These items often require protection on both sides to prevent damage during transport.

Industrial Manufacturing: In industries like automotive manufacturing and home appliance assembly, double-sided foam is used to bond or secure parts, providing strong, long-lasting adhesion to keep components stable during operation.

Advertising and Displays: Double-sided foam is commonly used in advertising and display board manufacturing. Its ability to bond multiple surfaces makes it ideal for creating secure and durable displays for marketing materials, signage, and exhibitions.

Home Decoration: Single-sided foam is frequently used in home decor applications such as attaching wallpapers, mirrors, and picture frames. With its moderate adhesive strength, it is ideal for securing lightweight decorative items.

Packaging and Logistics: Single-sided foam is commonly used in logistics packaging to secure items within boxes or containers, preventing shifting during transportation. It is effective for safeguarding items without needing high-strength bonding.

Electronic Product Protection: Single-sided foam is often used as a protective film for electronics, such as screen protectors for mobile phones and monitors. It helps isolate and protect the surface of electronic devices.