Cat:Glue -coated Protective Film

● Good weatherability for outdoor exposure; ● Stable adhesion level; ● UV resistance for up to 12 months; ● Can print customized logo or application i...

See Details

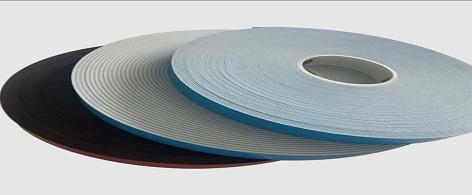

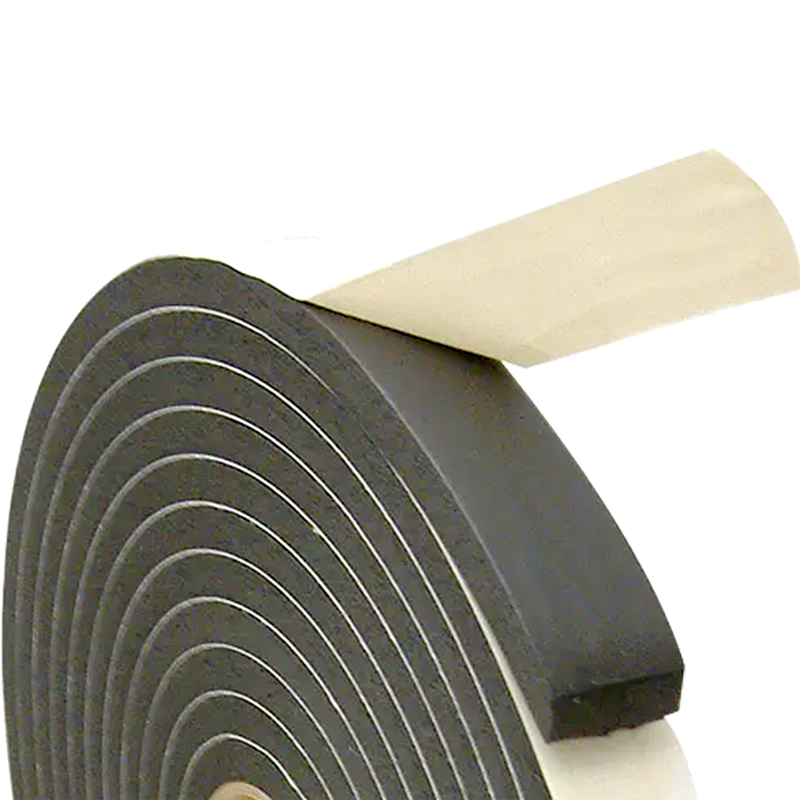

Double-sided foam tape is a unique and versatile adhesive solution that has seen widespread use across various industries. It consists of a foam core sandwiched between two layers of strong adhesive, allowing it to provide a durable and secure bond for a wide range of materials and surfaces.

The key durability features of double-sided foam tape lie in its material composition and design. The foam core provides several advantages that enhance the performance of the tape over long periods of use. Let’s explore these factors in detail:

The foam core of double-sided foam tape is compressible, allowing it to absorb shocks and vibrations effectively. This makes it ideal for applications where products or materials are subject to movement or impact, such as in the automotive, electronics, or construction industries. Unlike other adhesive tapes that may lose their bond under stress, the foam core maintains its shape and adhesive properties, even when subjected to vibrations or sudden impacts.

Another important durability feature of double-sided foam tape is its gap-filling capability. Unlike flat adhesive tapes, foam tape can conform to uneven and textured surfaces, filling in gaps and voids. This ensures a stronger and more secure bond in applications where the surface is not perfectly smooth. For example, foam tape is commonly used in mounting signs, trim, and panels in the construction and automotive sectors, where surface irregularities can otherwise weaken the bond.

Many double-sided foam tapes are specially formulated to perform well in extreme weather conditions. Whether exposed to high or low temperatures, UV radiation, or moisture, these tapes maintain their bond strength over time. This resistance to environmental factors makes double-sided foam tape a preferred choice for outdoor applications, such as mounting signage on building exteriors or securing parts on vehicles.

Double-sided cloth tape is another popular adhesive solution, but it differs significantly from foam tape in several key areas that affect durability. Here is how the two compare:

Double-sided cloth tape generally offers higher initial adhesion strength on smooth surfaces. However, it lacks the flexibility and shock-absorbing properties of foam tape. Over time, cloth tape may lose its bond when exposed to stress, vibrations, or uneven surfaces. Foam tape, with its compressible core, provides a more reliable and long-lasting bond in applications where flexibility and impact resistance are important.

Cloth tapes can degrade more quickly when exposed to moisture, UV rays, or extreme temperatures. Foam tapes, however, are specifically designed to resist these environmental factors. Whether it’s the heat of the summer sun, freezing winter temperatures, or exposure to rain, double-sided foam tape can maintain its performance in ways that cloth tapes cannot. For outdoor and heavy-duty applications, foam tape’s durability stands out as a critical advantage.

Cloth tapes tend to perform best on smooth, flat surfaces and may struggle to adhere properly to rough or textured materials. On the other hand, foam tapes can adhere to a wider variety of surface types, including those with irregularities. This makes foam tape ideal for a variety of mounting and sealing applications where surface conditions may vary.

Clear adhesive tapes, such as double-sided film tape, are often used for clean, discreet bonding applications. These tapes are typically thin and transparent, making them ideal for situations where aesthetics matter. However, in terms of durability, double-sided foam tape has several advantages over clear tapes:

Clear adhesive tapes are designed to provide strong initial adhesion to smooth surfaces. However, their bond strength tends to diminish over time, especially when exposed to environmental stress such as temperature fluctuations or moisture. Foam tape, due to its gap-filling properties and greater flexibility, provides a more durable and long-lasting bond under these conditions.

While clear adhesive tapes can provide an effective bond in dry, controlled environments, they tend to lose their effectiveness when exposed to extreme temperatures or outdoor conditions. Foam tape is engineered to handle these challenges, offering better resistance to UV rays, moisture, and high or low temperatures.

One of the main differences between clear adhesive tape and double-sided foam tape is the thickness and flexibility of the latter. Foam tape is thicker and more flexible, allowing it to adapt to uneven surfaces and absorb impacts. Clear tapes are generally thinner and more rigid, making them less suited for applications where movement or stress could compromise the bond.

Duct tape is often considered a go-to solution for quick fixes, but it doesn’t always provide the durability required for long-term applications. Here’s how double-sided foam tape compares:

Duct tape is a multipurpose adhesive that can bond to various surfaces but is primarily effective on rough, textured materials. Foam tape, on the other hand, excels in adhering to both smooth and uneven surfaces. While duct tape may provide a temporary bond, foam tape’s superior adhesion strength ensures a lasting hold on both flat and irregular surfaces.

Duct tape may lose its bond under stress, particularly when the materials it is holding are subject to vibrations or movement. Foam tape, with its shock-absorbing properties, can handle continuous stress and movement without compromising the bond. This makes it a more reliable option for applications where long-term durability is critical.

Duct tape is not as resistant to environmental factors such as UV radiation, moisture, and temperature extremes. Over time, duct tape can degrade when exposed to these elements. Foam tape is designed to perform well in a wide range of environmental conditions, making it ideal for outdoor or heavy-duty use.

While double-sided foam tape is inherently durable, several factors can influence its performance and longevity:

The type of environment where the tape is applied can have a significant impact on its durability. For instance, high-humidity areas may weaken the adhesive over time, while exposure to UV rays can cause the tape to break down. Many foam tapes are formulated with UV-resistant and weatherproof adhesives to counteract these issues.

Proper surface preparation is essential for achieving optimal adhesion. Surfaces that are dirty, oily, or contaminated with other substances can prevent the adhesive from forming a strong bond. Cleaning the surface before applying the tape ensures that the adhesive performs at its best.

The thickness of the foam and the type of adhesive used also influence durability. Thicker foam provides more cushioning and impact resistance, while high-quality adhesives offer superior long-term performance. Choosing the right foam tape for the specific application can make a significant difference in how long it lasts.

Double-sided foam tape is ideal for applications where durability, impact resistance, and weatherproofing are essential. Here are some industries and scenarios where foam tape excels:

In the automotive sector, foam tape is used for mounting trim, mirrors, and other components. Its ability to withstand vibrations, temperature changes, and exposure to the elements makes it the preferred adhesive choice in automotive assembly and repair.

Foam tape is widely used for mounting signs and panels in construction, as it offers a strong and lasting bond on various surfaces. It also provides a clean, discreet appearance, which is particularly important for aesthetic applications like signage and displays.

Double-sided foam tape is also used in electronics for securing components and providing shock absorption. Its ability to maintain a strong bond without damaging sensitive surfaces makes it perfect for applications where long-term reliability is crucial.

While there are many types of adhesive tapes, double-sided foam tape stands out in terms of durability. It offers superior resistance to environmental factors, maintains its bond strength under stress, and excels in applications where flexibility and impact resistance are critical. Whether for automotive, construction, or electronics, double-sided foam tape proves to be the most reliable option for demanding, long-term applications.

| Feature | Double-Sided Foam Tape | Double-Sided Cloth Tape | Clear Adhesive Tape | Duct Tape |

| Bond Strength | High, maintains over time | Moderate, loses bond with stress | Moderate, weakens with time | Moderate, can fail under stress |

| Weather Resistance | Excellent, UV and moisture resistant | Good, but weakens with moisture | Good, but degrades with UV exposure | Poor, degrades with UV and moisture |

| Surface Compatibility | Smooth and uneven surfaces | Best on smooth surfaces | Best on smooth surfaces | Works on rough surfaces |

| Shock and Vibration Resistance | Excellent | Poor | Poor | Moderate |