Cat:Glue -coated Protective Film

● Protect window glass against paint splatters, dirt, staining, and spillages during painting, building, plastering, tiling, general maintenance and r...

See Details

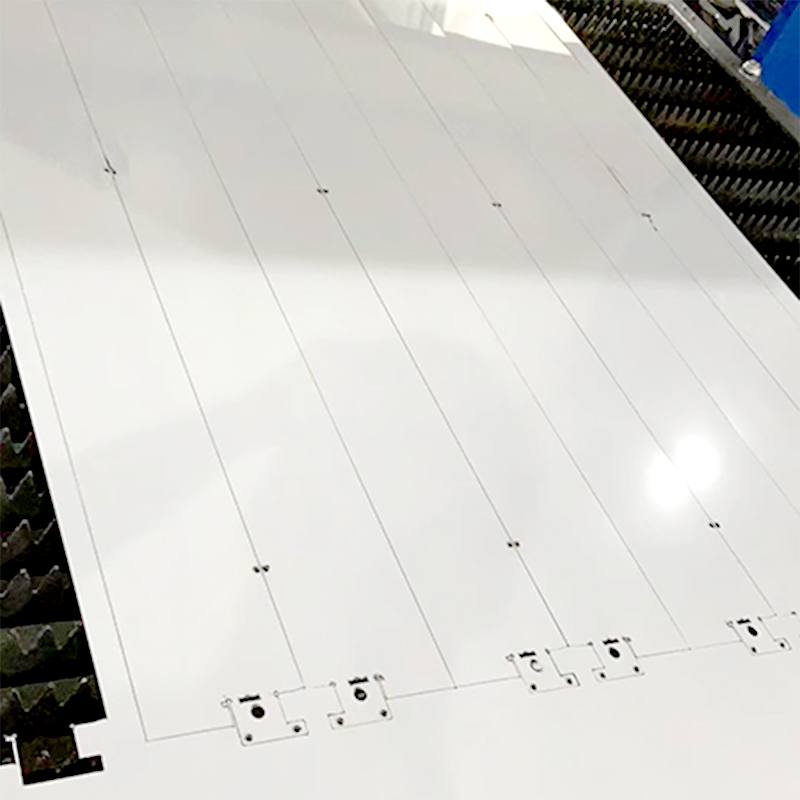

1. Surface Protection During Fabrication

During the manufacturing process of aluminum profiles, multiple processes such as sawing, punching, bending, and welding are required. These operations may cause metal debris, mechanical friction, tool collisions, etc., which can easily cause scratches, indentations, or contamination on the profile surface. Once the surface of the aluminum is damaged, it may lose its decorative and functional properties.

The protective film acts as a layer of "armor" during this period, effectively isolating it from external mechanical damage and particulate contamination. Especially for aluminum profiles with surface treatments such as high gloss, brushed, sprayed, or anodized, the protective film can ensure that the surface remains intact throughout the entire processing stage, avoiding rework and scrapping.

2. Prevention of Oxidation and Contamination

Although aluminum has a natural corrosion resistance, surface oxidation, discoloration, or oil stains may still occur in humid, high temperature, or chemical contact environments. For example, lubricating oil, coolant, fingerprints, or other contaminants in the workshop may corrode the aluminum surface in a short period of time.

Covering with a protective film can not only prevent air and moisture from directly contacting the aluminum, but also prevent fingerprints or stains generated by workers during operation from adhering to it. This is especially important in the manufacture of high-demand architectural decoration, electronic product housings or solar frame manufacturing.

3. Maintaining Aesthetic Quality

For aluminum profiles that require "appearance display" such as window frames, curtain walls, cabinet door panels, LED lamps, etc., whether the product surface is flawless is one of the core criteria for customers to purchase.

Even small scratches that are difficult to detect with the naked eye may be complained or returned by end users. The protective film can continuously provide surface protection throughout the entire production, storage, transportation and installation process, ensuring that each profile leaving the factory has a uniform gloss, tone and texture, enhancing the brand image and customer satisfaction.

4. Improved Efficiency in Handling and Transport

In the factory and logistics transportation process, aluminum profiles are usually stacked in batches, framed or conveyed through automated assembly lines. Without the protective film, the friction between them will cause scratches, which is especially common in long-distance transportation.

After using the protective film, the direct contact between products can be greatly reduced, and the dependence on cushioning materials during transportation and packaging can also be reduced. This not only increases the handling speed and reduces the complexity of operation, but also saves labor and packaging costs.

5. Cost Savings from Reduced Rework and Waste

A damaged aluminum profile often cannot be simply "polished and repaired", but the entire piece needs to be scrapped or reprocessed. This not only wastes materials and working hours, but may also delay delivery progress.

By using protective films, manufacturers can significantly reduce the surface defect rate, reduce returns or rework caused by scratches, oxidation, contamination and other problems, improve production line efficiency, and save a lot of operating costs in the long run.

6. Customization and Branding Opportunities

Many high-quality protective films can be customized according to customer needs, such as printing brand logos, product batch numbers, installation direction arrows or QR code information on the film. This not only facilitates traceability and assembly guidance on the production line, but also increases brand exposure in front of end users.

This combination of "function + publicity" provides companies with higher added value, while improving the overall product professionalism and market awareness.

7. Easy Application and Removal

Modern protective film products usually use low-viscosity or medium-viscosity glue, which can be quickly applied and easily removed after weeks or months without leaving glue marks on the surface of the aluminum profile. This is especially important for on-site construction after assembly, saving cleaning time and avoiding the risk of damaging the finished product.

High-quality protective films are also resistant to high temperatures and UV rays. Even if they are stored outdoors or exposed to sunlight for a long time, they will not change color or age, thus better adapting to different manufacturing and storage environments.