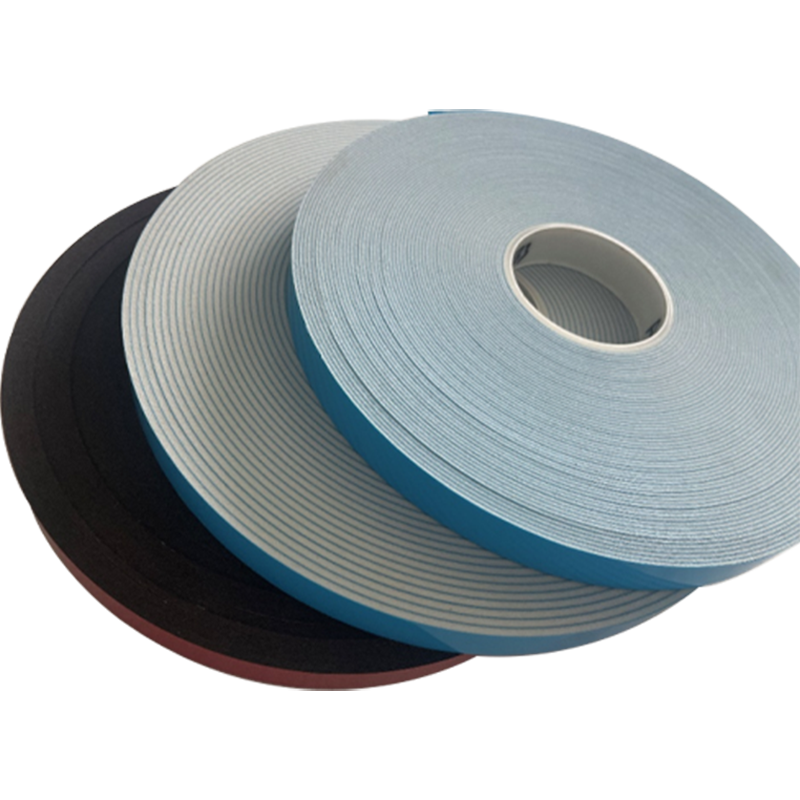

Exceptional Adhesion and Holding Power

One of the most significant advantages of double-sided foam tape is its exceptional adhesion and holding power. The foam core provides a flexible yet robust base that conforms to irregular surfaces, ensuring a secure bond even on uneven or textured materials. This makes it particularly useful for applications where traditional adhesives may struggle to maintain a strong hold.

For example, in the construction industry, double-sided foam tape is often used to mount wall panels, mirrors, and decorative trims. Its strong adhesive properties ensure that these elements stay securely in place, even in high-traffic areas or environments subject to vibrations and movement. This reliability reduces the need for additional mechanical fasteners, streamlining the installation process and enhancing the overall aesthetic of the finished project.

Versatility Across Various Applications

Double-sided foam tape is incredibly versatile, suitable for bonding a wide range of materials, including metal, glass, plastic, wood, and fabric. This versatility makes it an essential tool in many industries, providing a reliable adhesive solution for diverse applications.

In the automotive industry, for instance, double-sided foam tape is commonly used for attaching trim, badges, and emblems to vehicles. Its ability to withstand harsh environmental conditions, such as extreme temperatures, UV exposure, and moisture, ensures that these components remain securely attached over time. Additionally, the tape's cushioning properties help absorb shocks and vibrations, protecting delicate components and enhancing overall vehicle durability.

In the electronics industry, double-sided foam tape is used for assembling devices, securing components, and providing insulation. Its ability to bond different substrates effectively, coupled with its thermal and electrical insulation properties, makes it an invaluable tool for manufacturing and repairing electronic devices. For example, it can be used to attach heat sinks to circuit boards, ensuring optimal thermal management and device performance.

Ease of Use and Time Efficiency

Another key advantage of double-sided foam tape is its ease of use and time efficiency. Unlike liquid adhesives, which require curing time and may create a mess, double-sided foam tape provides an instant bond with minimal preparation. This makes it a convenient and efficient choice for both professionals and DIY enthusiasts.

In home improvement projects, double-sided foam tape can be used for a variety of tasks, such as mounting hooks, frames, and decorative items. Its quick application and strong hold allow homeowners to complete projects swiftly and with confidence. Additionally, because the tape is available in various widths and thicknesses, users can choose the appropriate size for their specific needs, ensuring a clean and professional finish.

2.How Does Double-Sided Foam Tape Enhance Durability and Longevity?

Double-sided foam tape is designed to provide long-lasting adhesion and durability, making it a reliable solution for applications requiring a permanent or semi-permanent bond. Its unique construction and high-quality materials contribute to its exceptional performance and longevity.

Resistance to Environmental Factors

One of the primary reasons double-sided foam tape is so durable is its resistance to environmental factors. The foam core and adhesive layers are engineered to withstand a wide range of conditions, including extreme temperatures, humidity, UV radiation, and chemicals. This resilience ensures that the tape maintains its adhesive properties and structural integrity over time, even in challenging environments.

For example, in outdoor applications, double-sided foam tape can be used to mount signage, secure fixtures, and seal joints. Its ability to resist weathering and UV degradation ensures that the tape remains effective and does not deteriorate, providing a long-lasting bond that can withstand the elements. This durability reduces maintenance requirements and extends the lifespan of the installations.

Shock Absorption and Vibration Dampening

Double-sided foam tape also excels in applications where shock absorption and vibration dampening are essential. The foam core acts as a cushion, absorbing impacts and reducing the transmission of vibrations between bonded surfaces. This property is particularly valuable in industries such as automotive and electronics, where components are subject to constant movement and mechanical stress.

In the automotive sector, for instance, double-sided foam tape is used to attach body panels, trim pieces, and interior components. The tape's cushioning properties help prevent rattling and reduce noise, enhancing the overall driving experience. Additionally, by absorbing vibrations, the tape helps protect sensitive components from damage, contributing to the longevity and reliability of the vehicle.

In electronics, double-sided foam tape can be used to mount delicate components, such as sensors, displays, and circuit boards. The tape's ability to absorb shocks and vibrations helps protect these components from mechanical stress, ensuring their optimal performance and longevity. This is particularly important in portable devices, such as smartphones and tablets, which are subject to frequent handling and impacts.

Strong Initial Tack and Permanent Bond

The strong initial tack of double-sided foam tape ensures an immediate bond upon application, providing instant holding power without the need for clamps or additional support. This feature is particularly advantageous in time-sensitive projects where quick assembly is required. Moreover, the tape's permanent bonding capability ensures that the adhesive remains effective over the long term, providing a reliable and durable bond.

For instance, in the construction of modular furniture, double-sided foam tape can be used to bond panels and components quickly and securely. The strong initial tack allows for rapid assembly, while the permanent bond ensures that the furniture remains sturdy and stable over time. This combination of quick application and long-lasting adhesion makes double-sided foam tape an ideal choice for manufacturers looking to streamline production processes and enhance product quality.

3.Why Is Double-Sided Foam Tape a Cost-Effective Adhesive Solution?

Reduced Material and Labor Costs

One of the primary ways double-sided foam tape reduces costs is through material and labor savings. Unlike traditional mechanical fasteners, such as screws, nails, and rivets, double-sided foam tape requires no additional hardware or tools for installation. This eliminates the need for pre-drilling, fastening, and finishing, simplifying the assembly process and reducing labor costs.

For example, in the signage industry, double-sided foam tape can be used to mount signs and displays without the need for brackets or frames. This not only reduces the amount of material required but also speeds up the installation process, allowing workers to complete projects more efficiently. The result is a significant reduction in both material and labor costs, enhancing overall profitability.

Minimized Downtime and Increased Productivity

The quick and easy application of double-sided foam tape also contributes to cost savings by minimizing downtime and increasing productivity. Unlike liquid adhesives, which require curing time, double-sided foam tape provides an instant bond, allowing work to proceed without delays. This is particularly beneficial in fast-paced environments where time is of the essence.

In manufacturing, for example, double-sided foam tape can be used to assemble components and products quickly and efficiently. The immediate bonding capability of the tape allows production lines to operate continuously, reducing downtime and increasing output. This increased productivity translates to cost savings and improved operational efficiency, making double-sided foam tape a valuable asset for manufacturers.

Long-Term Durability and Maintenance Savings

The long-term durability of double-sided foam tape also contributes to cost savings by reducing the need for repairs and maintenance. Its resistance to environmental factors and mechanical stress ensures that the adhesive bond remains strong and intact over time, minimizing the risk of failure and the associated costs of repairs and replacements.

For instance, in the construction industry, using double-sided foam tape to mount panels and fixtures reduces the likelihood of detachment and damage over time. This durability translates to fewer maintenance requirements and lower costs for repairs, enhancing the overall cost-effectiveness of the project. Additionally, the tape's long-lasting performance ensures that installations remain secure and reliable, providing peace of mind for both contractors and clients.

English

English

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى