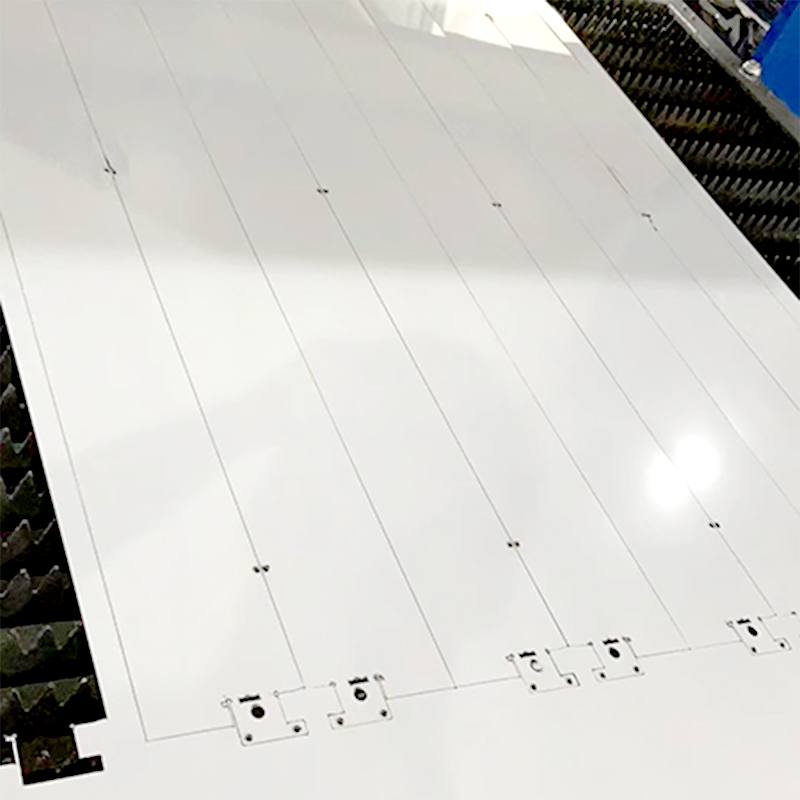

When embarking on a new project, whether it's in the automotive, electronics, or construction industry, protecting your surfaces from scratches, dust, and other contaminants is of utmost importance. Glue-coated protective films offer a comprehensive solution that goes beyond mere coverage. They are designed to adhere tightly to a wide array of materials, from delicate glass panels to rugged metal components, ensuring a seamless fit that withstands even the toughest handling conditions.

Unlike traditional protection methods, such as foam padding or cloth covers, glue-coated films provide a layer of protection that is both invisible and unobtrusive. They allow for easy inspection of the underlying surface without the need to remove the film, saving time and reducing the risk of accidental damage during the removal process. Moreover, their self-adhesive backing eliminates the need for additional tapes or fasteners, making them a more eco-friendly and cost-effective alternative.

Our glue-coated protective films are also engineered to withstand extreme temperatures and humidity levels, ensuring that your surfaces remain protected from environmental factors during transportation, storage, or even during the manufacturing process itself. This versatility makes them the ideal choice for a wide range of industries and applications, where reliability and durability are non-negotiable.

2.How Do Glue-Coated Protective Films Enhance Efficiency and Reduce Costs?

Efficiency and cost-effectiveness are two of the most critical factors in any industrial or construction project. Our glue-coated protective films are designed to streamline processes and minimize waste, leading to significant cost savings and improved productivity.

The ease of application of our films significantly reduces labor costs. With their self-adhesive backing, they can be applied quickly and easily by even novice operators, eliminating the need for specialized equipment or training. This not only saves time but also frees up resources that can be allocated to other critical tasks.

Our films offer superior protection against scratches, dust, and other contaminants, reducing the risk of costly repairs or replacements. By safeguarding your surfaces from accidental damage, you can avoid the need for rework or refinishing, which can be both time-consuming and expensive.

Another key advantage of our glue-coated protective films is their residue-free removal. Once the film is no longer needed, it can be easily peeled off without leaving behind any sticky residue or damaging the underlying surface. This eliminates the need for extensive cleaning or refinishing, further boosting efficiency and reducing costs.

We prioritize quality above all else. We use only the finest materials and cutting-edge manufacturing techniques to produce our films, ensuring that they are durable, transparent, and resistant to UV rays, humidity, and temperature fluctuations. This commitment to quality is reflected in every aspect of our products, from their seamless adhesion to their superior protective properties.

In addition to quality, we also place a strong emphasis on innovation. Our R&D team is constantly pushing the boundaries of what's possible, developing new formulations and technologies that meet the evolving needs of our customers. Whether you're looking for a film that can withstand harsh chemicals or one that is designed specifically for curved surfaces, we have a solution that fits your needs.

Customization is another key aspect that sets our glue-coated protective films apart. We understand that every project is unique, and that's why we offer custom-sized films to fit your specific requirements. Whether you need a film for a small component or an entire wall, we can provide a solution that fits perfectly. Our dedicated support team is always on hand to assist you with your measurements and ensure that you receive a film that meets your exact specifications.

English

English

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى